Service

We offer our customers an extensive range of services relating to their systems from various manufacturers: from planning services to servicing, maintenance, repairs and modifications to the sale of spare parts.

We offer you a comprehensive service package that you can tailor to your needs:

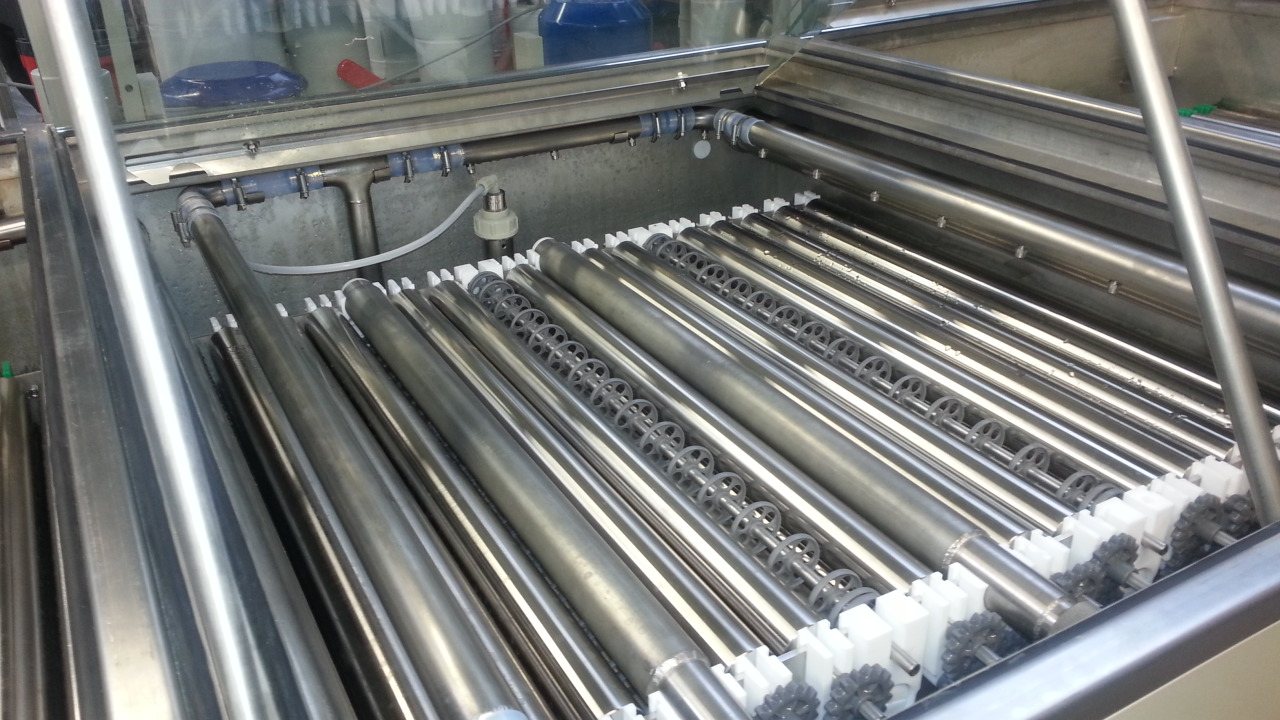

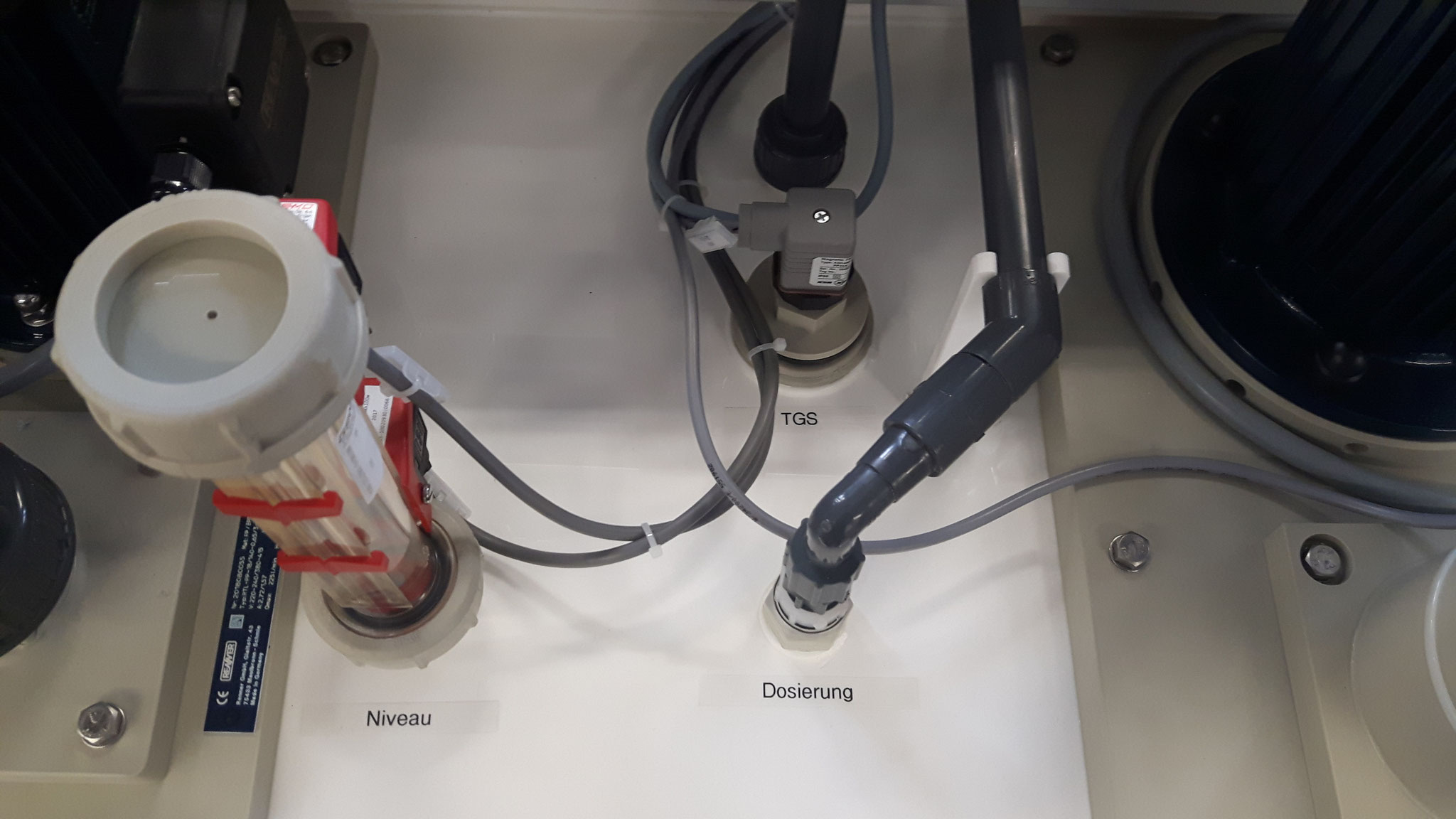

overhaul

Repairs

Plant optimization

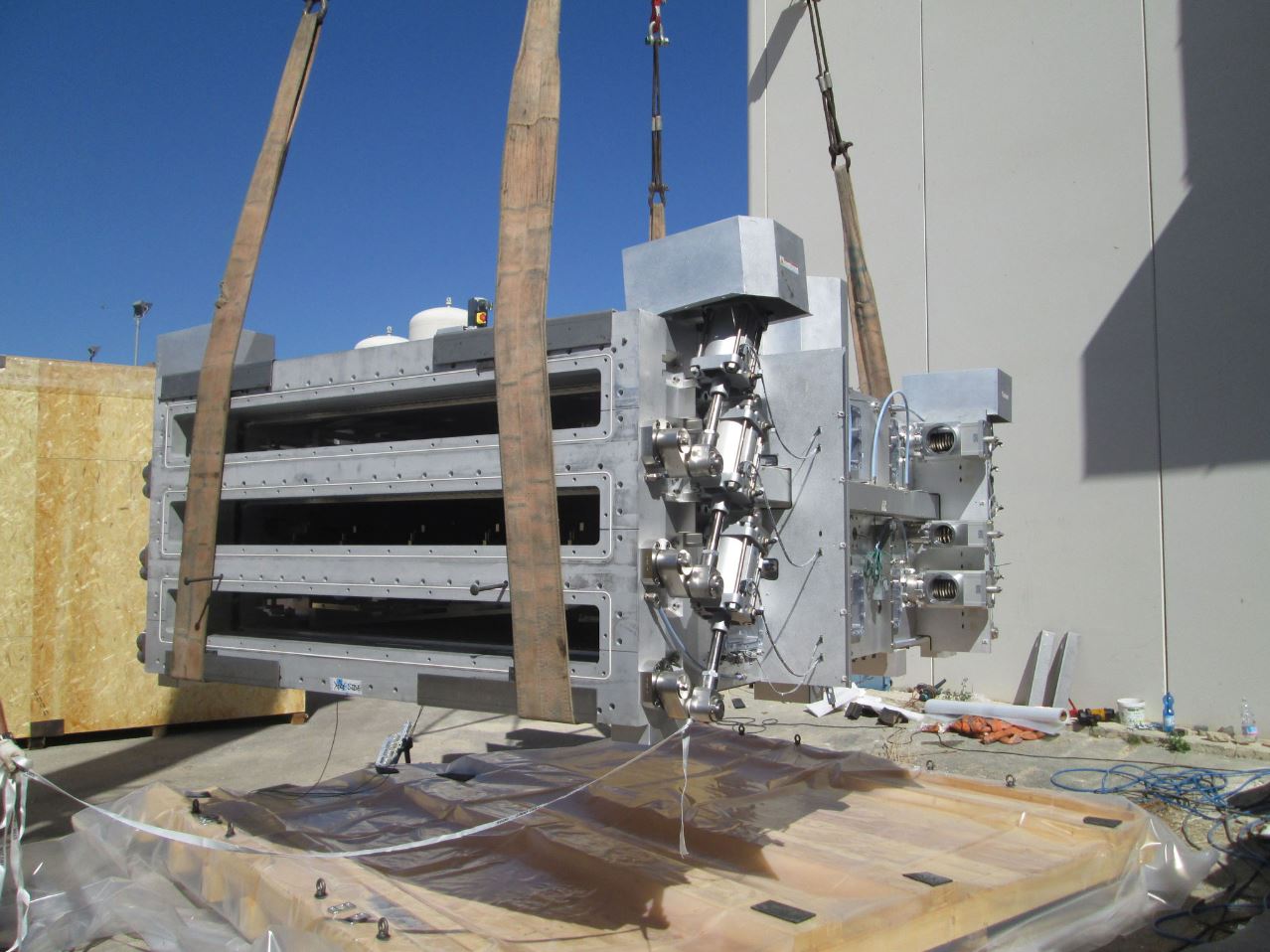

Removals modernization

Reseal

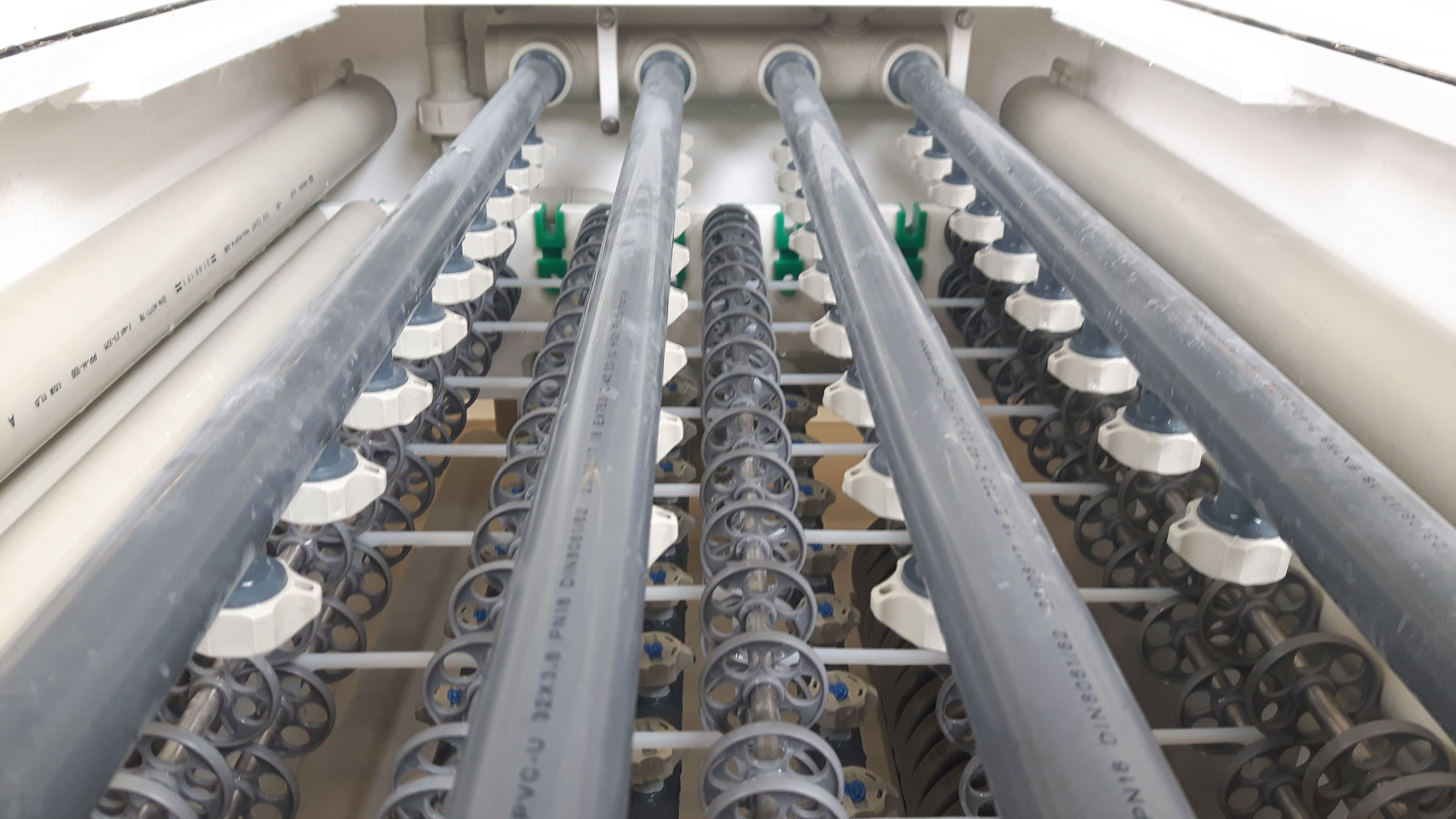

Piping work

New assemblies

Dismantling

Creation of new

system controls

Service maintenance contracts

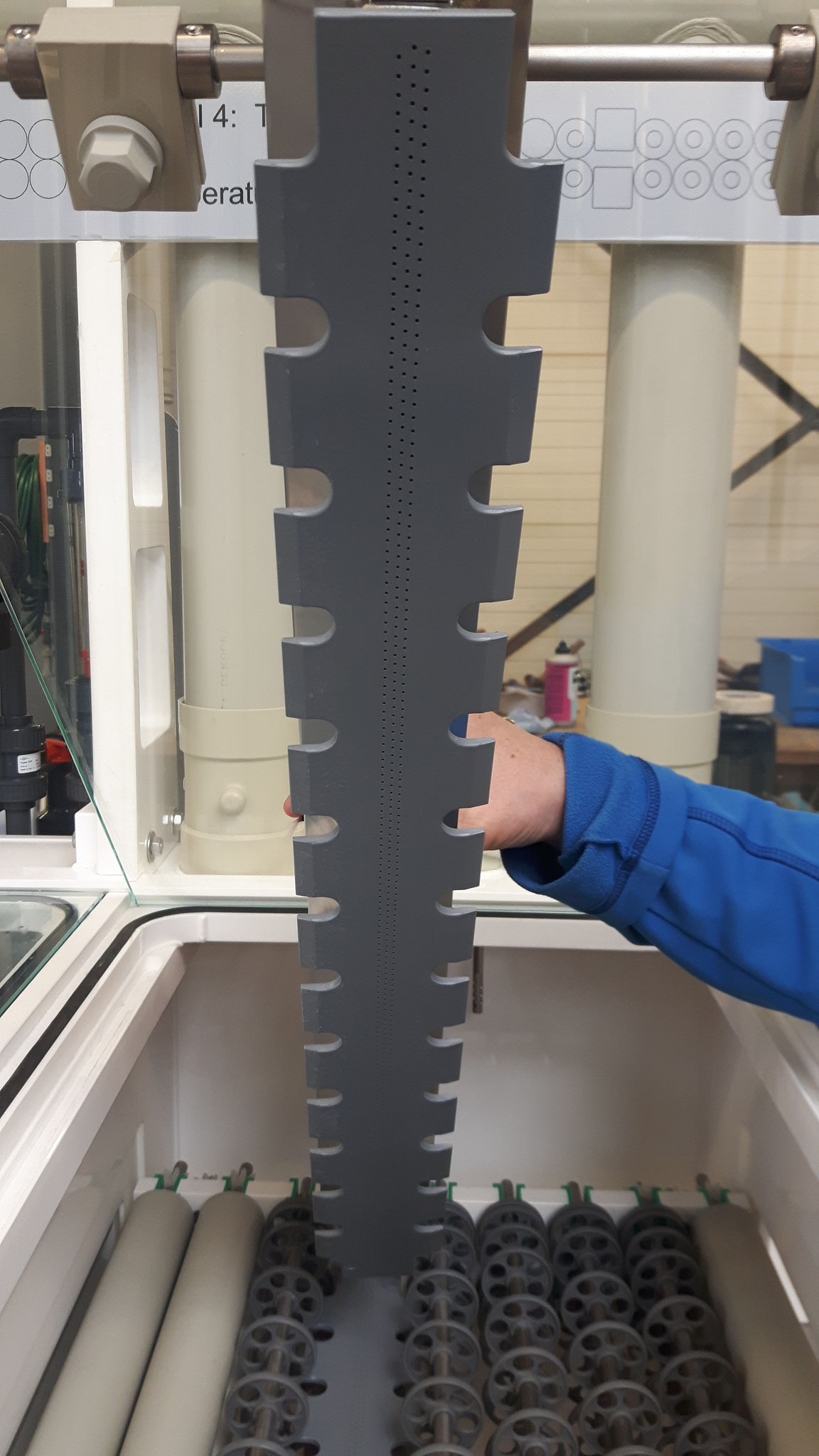

In the area of general plastics processing, our modern processing units enable us to manufacture high-precision series and sample parts. We also process a whole range of thermoplastics (PP, PPS, PE, PVDF, PVC …)

Quality and perfection are particularly important to us. We are therefore constantly checked for specialist knowledge and quality by independent testing facilities (SKZ, TÜV, DEKRA). We can offer you the highest level of security through proof of specialist company status in accordance with Section 19 1 WHG.

Contact Us!

You have any questions or suggestions ? Then feel free to contact us at any time. Our team will take care of your request immediately.